In industrial machinery, how motion stops is just as important as how it starts. Abrupt deceleration creates high peak forces that transfer directly into machine frames, bearings, and mounts. That accelerates wear and increases the risk of failure. As equipment speeds increase and tolerances tighten, these force spikes become harder to ignore.

Soft contact is the controlled alternative. By gradually building resistance at the point of impact, industrial shock absorbers designed for soft contact reduce peak loads while maintaining precise, repeatable motion control. The result is smoother deceleration, longer component life, and more reliable system performance.

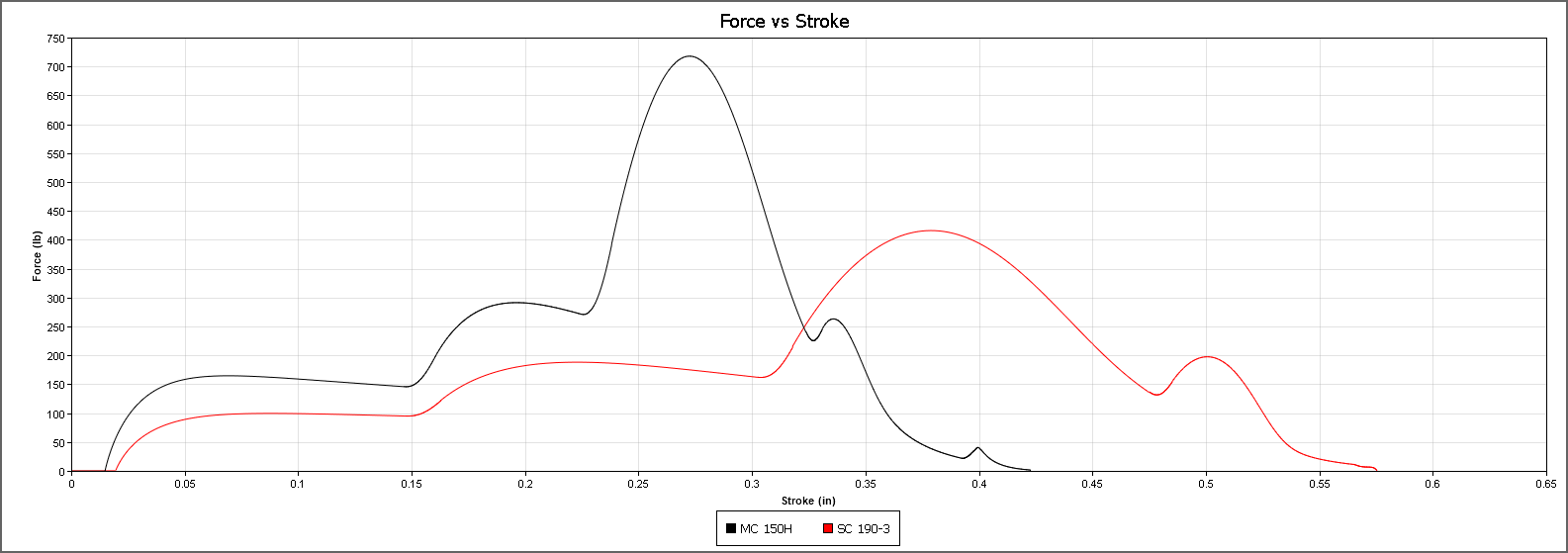

Soft contact in industrial shock absorption is achieved through deliberate hydraulic design choices that control how force develops throughout the stroke. In soft-contact shock absorbers, a slightly longer effective stroke is used to spread reaction forces over a greater distance, reducing peak loads. Larger orifice openings at the beginning of the stroke allow oil to flow more freely, keeping initial impact forces low, while progressively tightening orifices increase resistance as the stroke continues. This approach creates a smooth transition from motion to deceleration rather than an abrupt force spike. The result is not only lower peak forces, but also a noticeably gentler stop that reduces impact noise and strain on both equipment and handled loads—making soft-contact designs especially effective in handling and automation applications involving sensitive or noise-critical systems.

Soft contact delivers measurable performance benefits across industrial systems by reducing structural stress on machine frames and mounting components while minimizing wear on bearings, guides, and actuators. By lowering peak impact forces, it improves overall system stability and vibration control, which helps extend equipment life and reduce maintenance demands. Just as importantly, soft contact supports consistent, repeatable motion: an essential requirement in automated environments. These advantages are most evident in end-of-travel control for linear slides and actuators, high-speed automation and robotics applications such as pick-and-place systems and gantries, material handling and conveyor systems, AGVs and mobile equipment, and any application involving sensitive tooling or delicate product handling where uncontrolled impact can compromise performance or product quality.

Selecting a soft-contact shock absorber starts with understanding the application’s operating conditions, including load mass, impact velocity, available stopping distance, and expected cycle rate. Environmental factors such as temperature extremes or contamination exposure also influence performance, as does the choice between fixed or adjustable damping depending on how often operating parameters change. At ACE Controls, soft contact is engineered through carefully matched damping profiles that deliver predictable, repeatable deceleration under real-world industrial loads. By combining proven standard solutions with application-specific customization and engineering support, ACE helps ensure each shock absorber is sized and tuned to achieve optimal soft-contact performance, backed by tools and expertise that simplify selection and integration.

Soft contact is not simply a way to reduce impact. It is a deliberate design choice that improves how industrial systems perform over time. By controlling deceleration and minimizing peak forces, soft-contact shock absorbers protect equipment, stabilize motion, and support the precision demanded by modern automation. When deceleration is engineered as carefully as acceleration, machines run smoother, last longer, and require less maintenance. For engineers focused on reliability, repeatability, and long-term performance, soft contact is not an optional feature; it is a critical component of effective motion control design. While the design differences may appear simple, their impact on force, noise, and system longevity can be significant