Engineers often focus on how efficiently systems accelerate and move, but system longevity and reliability are often determined by how well motion is stopped. Uncontrolled impacts at end positions introduce force peaks that shorten component life, increase noise, and create unnecessary maintenance demands. Hydraulic industrial shock absorbers are designed to manage these loads by providing controlled deceleration tailored to the moving mass and speed involved. While this technology is well established in machine construction and automation, its importance extends into many applications outside traditional industrial settings.

From high-throughput car wash installations to camera systems operating at broadcast speeds and even particle accelerator facilities, ACE Controls industrial shock absorbers quietly ensure motion remains controlled, repeatable, and safe.

Keeping Automated Car Wash Systems Running Faster and Longer

Modern automated car washes have to run continuously in wet, chemically aggressive environments where motion components are constantly exposed to moisture and detergents. In one installation, pneumatically driven swivel arms carrying heavy wash brushes required smooth, rebound-free deceleration to maintain cycle times and protect the structure, but conventional dampers were corroding under operating conditions. Working with the system designers, ACE Controls helped transition the application to stainless steel, self-adjusting industrial shock absorbers. Capable of resisting corrosion while providing consistent deceleration, they operated even with variations in brush weight caused by water absorption. The result was improved uptime, reduced maintenance requirements, and more reliable operation, showing how proper end-of-stroke damping directly impacts performance even in high-use, everyday systems.

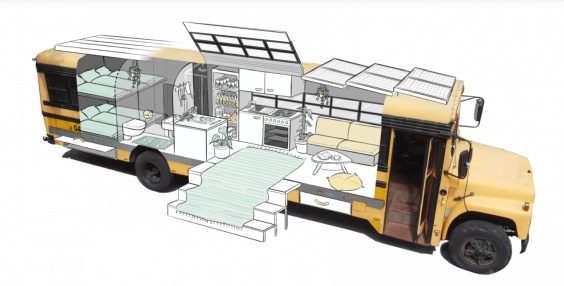

Turning a School Bus into a Mobile Event Space

Converting a retired U.S. school bus into a mobile event and living space introduced an unusual motion-control challenge: cutting a nearly three-meter-wide side wall to open and create an outdoor terrace. It also had to move safely and smoothly without relying on powered systems. As the build progressed and structural reinforcements increased the panel’s weight, standard components were no longer sufficient to control the motion safely across varying operating temperatures. Working with the conversion team, ACE Controls supplied custom-sized industrial gas springs tuned to handle the oversized moving mass, allowing the large side panel to open and close smoothly with minimal effort while maintaining safe, controlled motion: showing how properly engineered motion assistance solutions can enable large movable structures even in one-of-a-kind mobile applications.

Protecting High-Speed Camera Systems on Film and Television Sets

Modern film and broadcast productions rely on remote-controlled camera dollies that move rapidly and precisely along track systems, but that movement has incredible risks. Any uncontrolled impacts can damage cameras worth six figures while also causing costly recalibration delays and unwanted noise on set. Traditional rubber buffers proved insufficient as camera speeds and precision demands increased, prompting system designers to seek a safer, quieter solution. By integrating hydraulic safety shock absorbers from ACE Controls at track end positions, moving camera systems can now be brought to a controlled, rebound-free stop even in emergency situations, reducing structural stress while maintaining the quiet operation required during filming. Even in action movies, advanced damping solutions play a critical role in keeping modern production equipment both safe and operational.

Protecting Athletes and Equipment in Sports Science Testing

At the University of Tübingen’s Institute of Sports Science, specialized training and testing equipment is used to measure explosive force in movements such as javelin and handball throws. Using rapidly accelerated sled systems generated significant inertial forces at the limits of travel, but early attempts gathering data using simpler mechanical stops proved unreliable and raised safety concerns. This prompted engineers to integrate adjustable industrial shock absorbers from ACE Controls to provide controlled, rebound-free deceleration at both ends of the system’s motion. The result is a safer testing environment that protects both athletes and sensitive research equipment while allowing repeated measurements under varying test conditions. Precision damping solutions contribute not only to machine protection, but also to user safety in performance research environments.

Safeguarding Motion Systems Inside Particle Accelerator Research Facilities

At the GSI Helmholtz Centre for Heavy Ion Research in Darmstadt (home to the future FAIR accelerator facility) high-performance linear motor systems move precision components within experimental accelerator rings. Any slight malfunction that allows motion beyond defined travel limits risks incredibly expensive damage to highly sensitive and extremely costly equipment. To provide a mechanical safeguard in these rare emergency scenarios, engineers integrated adjustable industrial shock absorbers from ACE Controls at the end positions of critical linear units, making sure that all moving masses can be safely brought to a stop without rebounds if drive systems fail. Even in cutting-edge research environments designed to study matter under extreme conditions, reliable motion control remains essential to protecting equipment and maintaining uninterrupted scientific operations.

While industrial shock absorbers are often associated with factory automation and heavy machinery, these applications highlight how widely the need for controlled deceleration extends. Whether keeping high-throughput car washes running reliably, enabling large moving structures in custom vehicle builds, protecting high-speed camera systems, safeguarding athletes during performance testing, or serving as a fail-safe in advanced research facilities, the underlying engineering challenge remains the same: moving mass must be stopped safely and predictably.