Unfortunately, The Deschner Corporation is shutting down all operations, leaving many maintenance teams, engineers, and purchasing managers uncertain about what comes next. Deschner components have been widely used for decades, especially in automated equipment, machining, assembly lines, and industrial testing, so the closure raises a critical question:

What are some Deschner replacement options for manufacturers?

This post walks you through how ACE Controls can help you maintain performance, safety, and reliability with equivalent or upgraded solutions.

How Long Do You Have?

Because Deschner has officially ended production, inventory is already limited. Many distributors are selling through remaining stock, but availability is shrinking quickly and lead times are unpredictable. As the remaining inventory dries up, sourcing exact Deschner replacements will only become harder.

If you have Deschner shock absorbers or feed controls in operation, now is the best time to begin identifying replacements. Transitioning early helps you:

- Avoid unexpected downtime

- Prevent mismatched or low-quality third-party substitutes

- Ensure long-term maintenance consistency

- Upgrade to more durable, higher-capacity components where beneficial

ACE Controls offers direct or near-direct equivalents for many popular Deschner models. In several cases, ACE replacements provide improved performance or longer life.

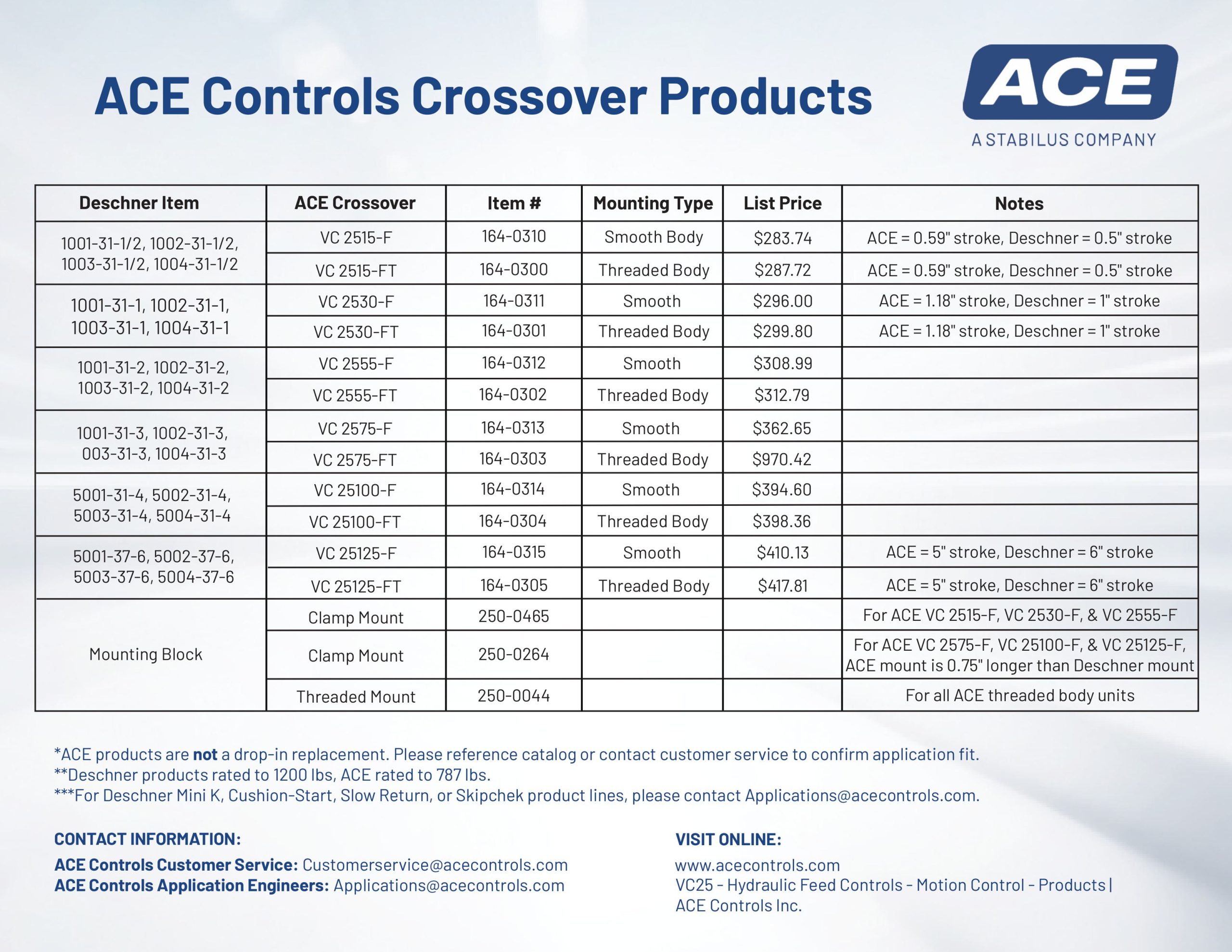

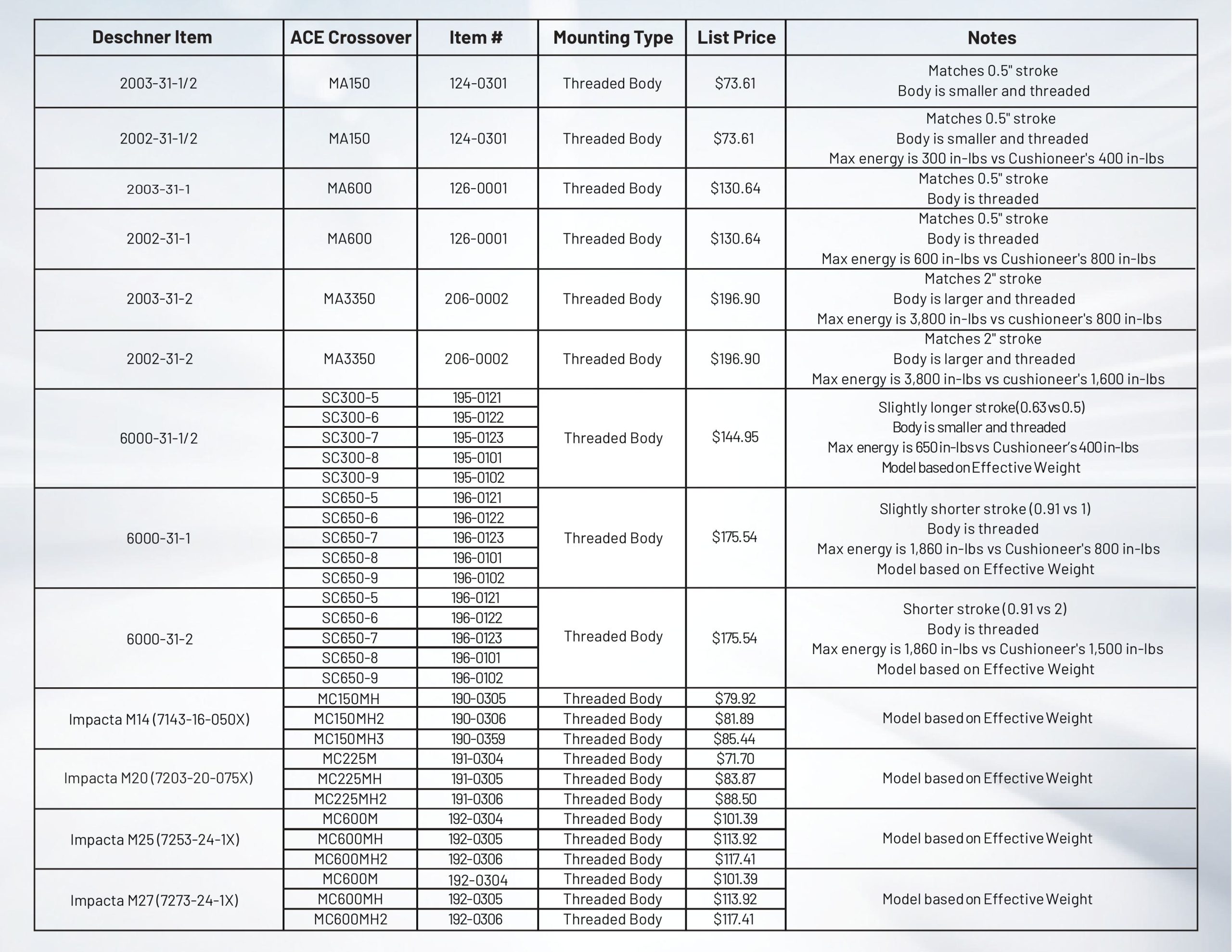

The Best Replacement for Each Deschner Part

How To Make the Switch Smoothly

Identify All Deschner Products in Operations

Replacing motion-control components can be straightforward, but only if you take the right steps to understand what you currently have and how each replacement will perform in your equipment. A smooth transition starts with a clear picture of every Deschner unit in operation. Begin by identifying all installed components and noting their model numbers, mounting details, stroke lengths, cycle frequency, and operating conditions. Even seemingly small variables, like a slightly different impact velocity or mounting orientation, can influence which ACE Controls product is the best match.

Create a Replacement Plan

Once you’ve completed your audit, the next step is to create a structured replacement plan. ACE can assist by recommending the proper equivalent for each Deschner model, outlining upgrade opportunities where higher capacity or longer service life may be beneficial, and providing accurate lead times and stocking options. In many cases, an ACE replacement not only matches your current performance requirements but offers improved durability, more precise adjustability, or greater energy absorption, giving you a chance to strengthen long-term system reliability rather than simply swapping parts

Document Changes As They’re Updated

As replacements are installed, it’s important to document the updates in your maintenance system. Recording the new ACE part numbers, installation dates, and any configuration notes ensures consistency across teams and helps avoid future confusion when ordering parts. Clear documentation also simplifies maintenance planning, especially for high-cycle equipment where components are serviced frequently.

Need Help Identifying a Replacement?

If you’re unsure which ACE product is the right fit for your application or if you simply want confirmation before making the switch, our application engineers are here to help. A model number, nameplate photo, or a brief description of your operating conditions is often all we need to identify the ideal replacement. We’re committed to making your transition seamless, straightforward, and fully supported.