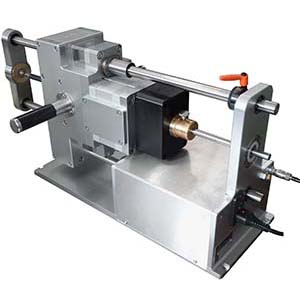

When it comes to the cutting operations to make power cables, safety is key. That’s why Rittmeyer, a German-based precision engineering company, utilizes a high-tech, coax shielding cutting device called the BERI.CO.CUT. To make operation of this electro-pneumatic machine safer, Rittmeyer integrated ACE shock absorbers and clamping elements into its design.

End Position Protection. The BERI.CO.CUT precision-cuts the shielding and braids cables used in electric and hybrid vehicles. As the cables are being worked on, the head of the machine moves. To protect operating personnel and the machine itself, Rittmeyer, along with ACE specialists, selected miniature format MC75EUM-3 shock absorbers.

These maintenance-free, hydraulic elements ensure gentle impact of the head against the rear pane, preventing costly damage to both the head and overall structure. And with a net weight of only 30 grams, a length of 70 mm and a reset time of 0.3 seconds, ACE shock absorbers far exceeded the cable cutting machine’s compact requirements.

Pneumatic Rod Clamping. In addition to the shock absorbers, Rittmeyer selected ACE LOCKED PN clamping elements to use in its cable cutting machine. These components are designed to immediately clamp in the event the machine loses pressure as it moves concentrically along two guide shafts, protecting both the operators and the machine itself. They also prevent movement during the cutting process—a critical function, as even the slightest cutting inaccuracy can have serious repercussions in automotive or aerospace applications.

Suitable for rods with diameters of 20 to 40 mm, LOCKED PN clamping elements absorb forces axially and rotationally. With a holding force of up to 36,000 N, they also reach or exceed the levels of hydraulic clamps without the high cost.