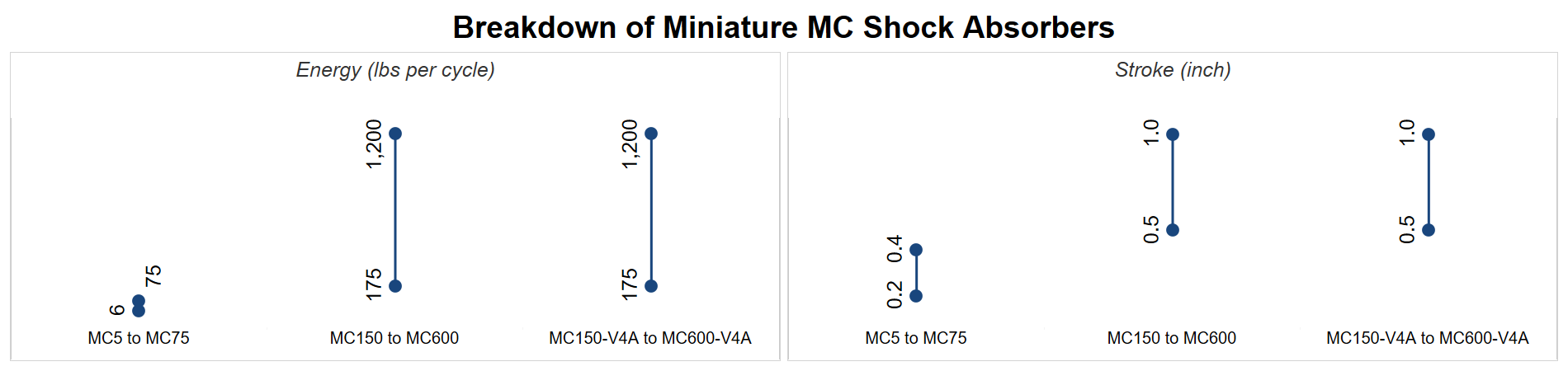

The ACE Controls’ MC Line boasts an impressive repertoire of shock absorbers that are engineered to deliver unparalleled performance across diverse applications. From the most delicate miniature machinery to extreme temperature demands, this comprehensive product range promises to conquer motion control challenges with finesse. To simplify the process of finding the perfect shock absorber match, we’ve devised two insightful charts as your ultimate selection guides. These invaluable visualizations can empower you to make informed decisions, allowing you to choose the ideal shock absorber from the MC Line that precisely fits your unique requirements. Each line is summarized below with links to allow for easy navigation!

Miniature Lines

MC5 to MC75

The MC5 to MC75 shock absorbers from ACE are miniature-sized and ideal for compact, efficient designs, providing short overall lengths and low return forces. These maintenance-free hydraulic machine elements feature a continuous outer body thread, integrated positive stop, and temperature-stable oil, offering a wide range of energy absorption. Their versatility makes them well-suited for various applications, including rotary actuators, automation, material handling, robotics, and more in industries like electronics, medical, and light industrial manufacturing.

MC150 to MC600

The MC150 to MC600 shock absorbers from ACE offer exceptional endurance and the lowest resetting force. Their hermetically sealed rolling diaphragm technology allows for a lifetime of up to 25 million cycles and low return forces. These maintenance-free and ready-to-install absorbers feature progressive energy capacities and compatibility with impact angles up to 25°, when a side load adapter is installed, making them suitable for various applications, including material handling equipment, packaging equipment, medium robotics, and machine tools. They can also be installed inside a cylinder for end stop damping in pneumatic systems.

MC150-V4A to MC600-V4A

The MC150-V4A to MC600-V4A shock absorbers are high-performance stainless steel miniature shock absorbers, offering exceptionally high endurance and corrosion protection. Based on the MC150 to MC600 product family, they feature ACE’s proven damping technology with a rolling diaphragm for maximum service life and direct installation in pressure chambers up to approximately 100 psi (7 bar). These self-compensating shock absorbers provide perfectly progressive energy absorption, and with their stainless steel construction (AISI 316L) and a complete range of stainless accessories, they are ideal for medical, electro-technology, marine, packaging, and chemical applications. They can also be filled with food-grade oil for use in food processing applications.

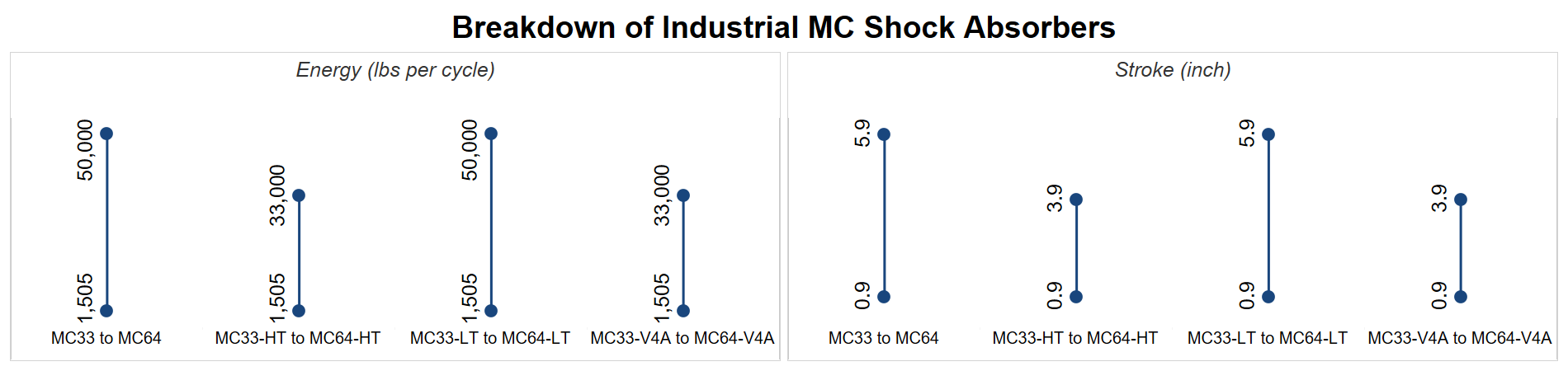

Industrial Lines

MC33 to MC64

The MC33 to MC64 shock absorbers from ACE’S MAGNUM range offer high energy absorption and a robust design. They feature the latest damper technology with self-compensating capabilities, providing longer service life and wide damping range, making them highly advantageous for various industrial automation and machine engineering applications.

MC33-V4A to MC64-V4A

The MC33-V4A to MC64-V4A shock absorbers from ACE’s MAGNUM range offer optimum corrosion protection with their stainless steel construction (AISI 316L) and special oil suitable for the food industry. These self-compensating industrial shock absorbers provide high energy absorption, a wide damping range, and a robust design, making them ideal for various industries, including food, medical, electronics, offshore, and more.

MC33-HT to MC64-HT

The MC33-HT to MC64-HT shock absorbers from the MAGNUM range are specifically designed for extreme high-temperature and high cycle applications. With special seals and fluids, they can operate reliably in temperatures ranging from 32 °F to 302 °F, offering a wide damping range and high energy absorption in a compact design. These self-compensating industrial shock absorbers are well-suited for challenging conditions and find applications in plant, industrial automation, and machine engineering.

MC33-LT to MC64-LT

The MC33-LT to MC64-LT shock absorbers from the MAGNUM range are designed for extreme low-temperature applications, with the capability to function reliably in temperatures ranging from -58 °F to +151 °F. These self-compensating industrial shock absorbers offer a wide damping range, high energy absorption in a compact design, and robust sealing technology, making them well-suited for various industrial, automation, and machine engineering applications, even under unfavorable conditions.